Rooflight Protection

Description

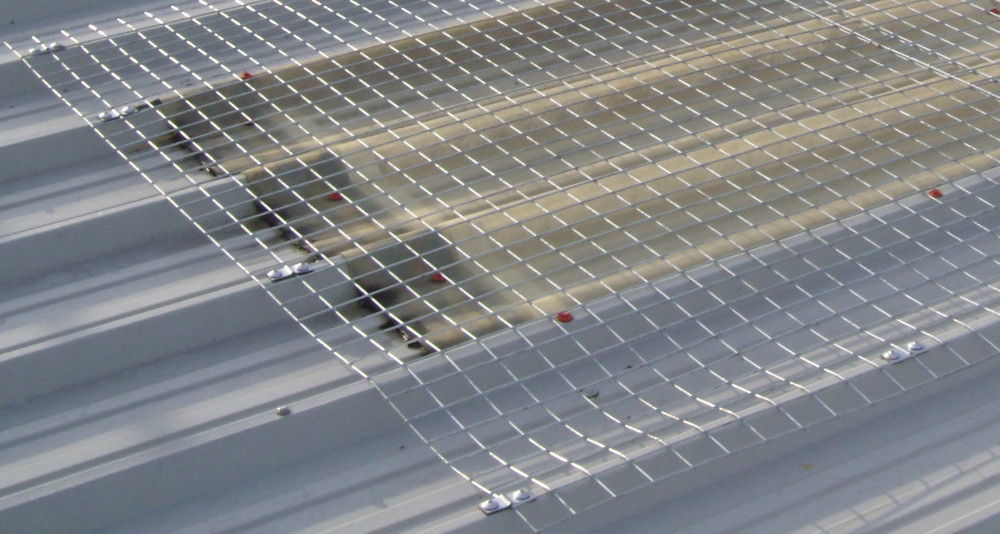

Roof Light Protection is designed to cover existing roof lights, providing a collective means of fall prevention, without blocking out light.

Falls through skylights are unfortunately all too common. Building owners have a duty of care to ensure workers who need to access a roof are safe, and yet if the roof lights are not cleaned on a regular basis they can become indistinguishable from the roof surface, which inevitably increases the risk of accidents. Over time, rooflights have the potential to become brittle and break very easily if someone stands on them.

Applicable UK Standards & Guidance

The test involves a 45Kg (100lbs) weight free falling from a distance of 1.2m (4’) to reach a maximum velocity. Class B rated products ensure the drop mass is retained but there is permitted some damage to the roof light.

1200 Joule test – This requires a 50Kg (110lbs) mass to be dropped from 2.4m (7.9’) and be retained by the roof light protection.

Levels of Safety

Roof Light Protection, as described above, provides a collective means of of fall prevention.

Design Considerations

Access & Maintenance Strategy

A formal Access & Maintenance Strategy Plan should be developed which considers the access & maintenance requirements of a building or structure over its life.

Access & Egress

Consideration should be given to how a user will access the roof. Will a means of access other than a permanent staircase be required e.g. Fixed vertical ladder, powered access equipment, secured portable ladder.

An edge protection or fall arrest system may be required if access to gutters, roof top plant & equipment that is adjacent to roof edges is required.

Design Loads

Consideration to the rating required. ACR Red Book specifies 3 rating levels:

Class C Non-fragile assembly – Following the first impact test, the test mass is retained on the test sheet

Class B Non-fragile assembly – A second test is carried out on the same test sheet and at the same location as the first test. The test mass is retained.

Class A Non-fragile assembly – On conclusion of the second drop, the test mass is removed and the assembly examined by the competent person. The assembly shows no significant signs of damage that will affect the long term strength & weatherability of the assembly.