Rooftop Cable Fall Protection Systems

Description

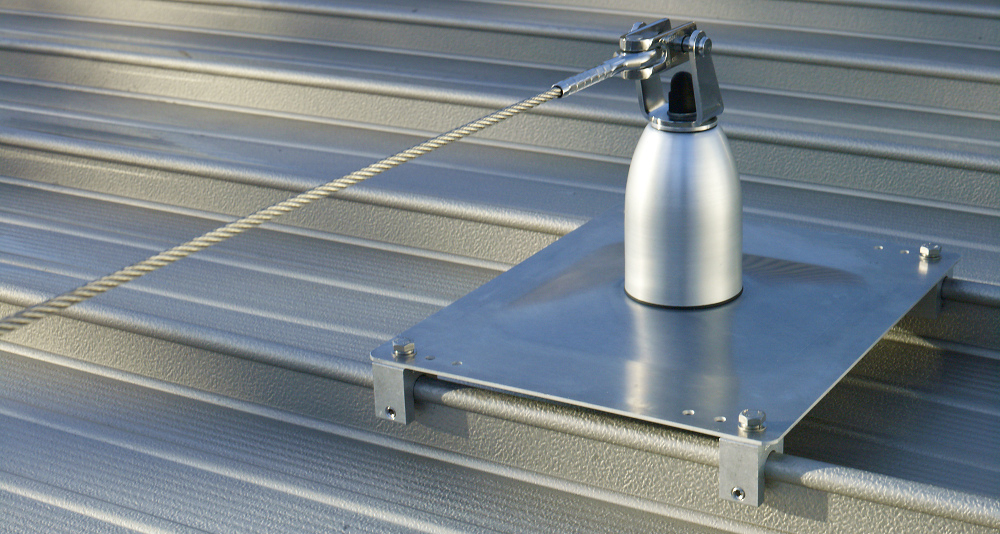

Rooftop cable fall protection systems are intended to provide continuous, safe access to rooftop plant & equipment, rain water outlets, gutters and other rooftop features that require periodic inspection or maintenance. They consist of two extremity anchors, and, depending on the length of the system and the access requirement, may include intermediate cable support posts and corner posts. Systems can be installed to a wide range of roof types via a variety of fixing methods and can accommodate a range of angles and changes in the contour of the roof to which they are installed.

Applicable UK Standards & Guidance

Personal fall protection equipment – Type C Anchor devices

Personal fall protection equipment — Anchor devices — Recommendations for anchor devices for use by more than one person simultaneously

Personal fall protection equipment. Anchor systems

Best Practice for the use of Horizontal Safety Lines in Roofwork

Testing of Roof Anchors on Roof Systems

BS EN 795 and the 89/686/EEC Directive

Levels of Safety

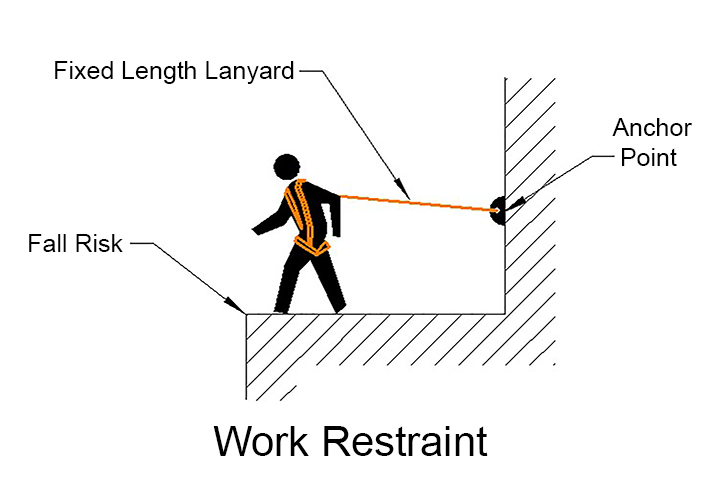

Work Restraint

Where it is reasonably practicable to do so systems should be designed in such a way as to provide Work Restraint. The position of the anchorage line together with the specified combination of user equipment will prevent the user from reaching a position from where they can fall.

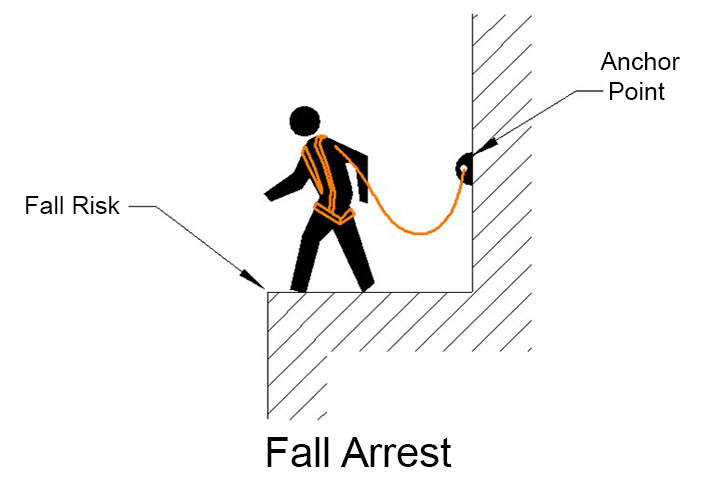

Fall Arrest

Where it is not reasonably practicable to install a system such that it provides Work Restraint, a Fall Arrest system can be installed. A Fall Arrest system will allow the user to reach a position from where they can fall, but minimise the distance and consequences.

Design Considerations

Access & Maintenance Strategy

A personal fall protection system should only be considered where designing out the risk or installing means of collective fall prevention, such as edge protection, are not reasonably practicable. A formal Access & Maintenance Strategy Plan should be developed which considers the access & maintenance requirements of a building or structure over its life.

Access & Egress

Consideration should be given to how a user will access the system. Will a means of access other than a permanent staircase be required e.g. Fixed vertical ladder, powered access equipment, secured portable ladder

The Layout

Where its is reasonably practicable to do so, the layout of the system should allow the user to reach all areas of the roof that require access and maintenance, without risk of a fall occurring i.e. Work Restraint.

Edge distances of no less than 2.30mtrs should be maintained where Work Restraint is specified, which allows for a maximum permitted 2.0mtr lanyard + 0.3mtr for the user. Consideration must be given to cable deflection, which will increase as the spacing between support posts increases.

Rooftop Cable Fall Protection Systems must not be installed on roof pitches greater than 15°.

Number of Users

How many simultaneous users will need to be connected to the system? Systems have limitations on the number of users that can be attached to the system, or be working in a single span.

Design Loads

Regardless of whether the system of work is Work Restraint or Fall Arrest, systems MUST be designed for fall arrest loads, consider the number of users simultaneously attached the the system and include a safety factor of at least two. The safety factor should be based on the maximum strength of the roof covering and supporting structure.

User Considerations

Competence

It is a requirement of the Work at Height Regulations 2005 that persons involved in work at height, including those planning, managing & supervising work at height are competent to do so.

Personal fall protection systems require a higher level of competence from the user than collective fall protection systems, such as edge protection. Fall Arrest systems require a higher level of competence from the user than Work Restraint systems.

Users of Rooftop Cable Fall Protection Systems must have the necessary level of knowledge, skill, experience & training in order to use the system safely.

User Equipment

The type of user equipment to be used with the system must be stated within the OEM Manual and its use, including dedicated travelling devices which are able to pass over intermediate and corner support posts, is critically important to the safe operation of the system.

For example, a system where the intended safe system of work is Work Restraint becomes Fall Arrest if the user selects, or is issued, a longer lanyard than specified. If there is insufficient clearance below the system in which to arrest a fall, incorrect selection of user equipment can have catastrophic consequences.

Rescue Planning

The Work at Height Regulations 2005 requires that the planning of work at height includes planning for rescue. When planning work with personal fall protection systems, it is critically important that a rescue plan is in place, along with the resources needed to effect a rescue i.e. trained and competent personnel, a rescue plan, suitable rescue equipment.

Energy Dissipation

In the event of a fall, the system is dynamically loaded. The end & corner anchor posts, in particular, will see high levels of energy, and this energy must be ‘removed’ from the system in order that the structure to which the system is fixed is not compromised.

Generally, there are two methods of energy dissipation employed by manufacturers of Rooftop Cable Fall Protection Systems.

Inline Energy Absorber

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Energy Absorbing Post

The primary benefit of energy absorbing posts is that in the event of a fall, the forces imposed on the roof structure are greatly reduced compared to a system that employs inline energy absorbers. Systems employing energy absorbing posts typically present a lower risk to the structural integrity of the roof, than a system that employs inline energy absorbers.

Inspection

Provision & Use of Work Equipment Regulations (PUWER)

Regulation 6 requires that inspections of work equipment are made and that records of the inspections are maintained.

Personal Protective Equipment at Work Regulations (PPEAW)

Regulation 7 obliges the PPE provider to ensure it is maintained in an efficient state

BS EN 365

Requirements, 4.4b, recommends that the periodic examination frequency shall be at least every 12 months.