Single Point Anchors

Description

Single point anchors provide an anchor point that is fixed to structure, for the attachment of personal fall protection and access systems.

They can take many different forms, from a simple eyebolt to being part of a roofpost. They are typically bonded into concrete using a special resin, or are bolted through steelwork, but can be fixed to a number of different kinds of structure using different fixing methods.

They all have a single attachment eye, some of which are fixed in place, others of which can rotate to self-align when under load.

Applications

Single point anchors may be designed for one or more of the following fall protection and access applications, using the application codes as stipulated in BS 8610: 2017.

- A1 Restraint

- A2 Fall-arrest

- A3 Rope access and work positioning

- A4 Rescue – accompanied descent

- A5 Rescue – remotely or self-operated – direct attachment

- A6 Rescue – remotely or self-operated – redirect attachment

- A7 Evacuation (emergency descent)

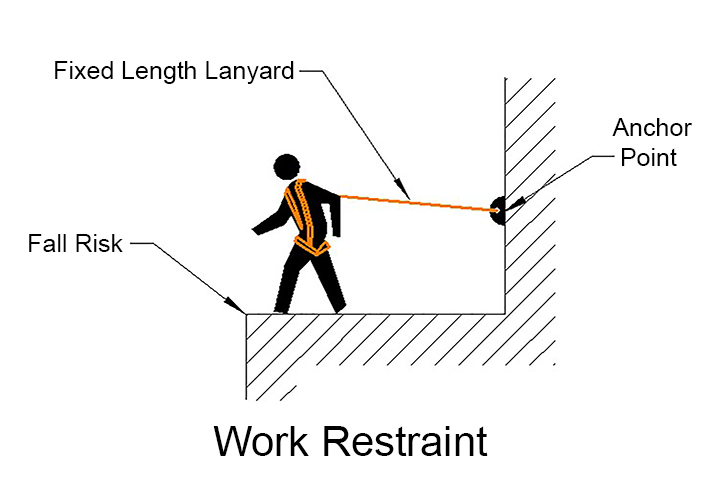

Restraint Application

Where fall protection is required and it is reasonably practicable to do so a restraint system should be installed. The position of the single point anchor together with the length of restraint lanyard will prevent the user from reaching a position from which a fall can occur.

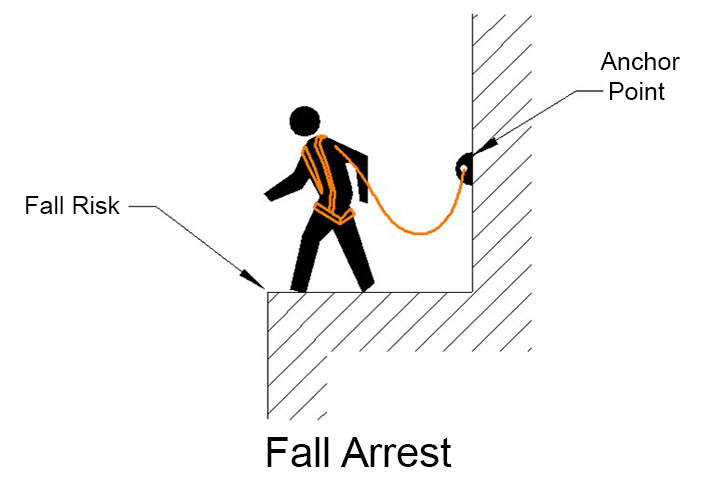

Fall Arrest Application

Restraint systems cannot provide fall protection where a user needs to move between two levels. A fall-arrest system can be used instead. Fall-arrest systems do not prevent falls, but will automatically stop a fall in a short distance should one occur. The choice of position of the single point anchor together with the performance of fall-arresting means is intended to stop the fall before the user can collide with the ground.

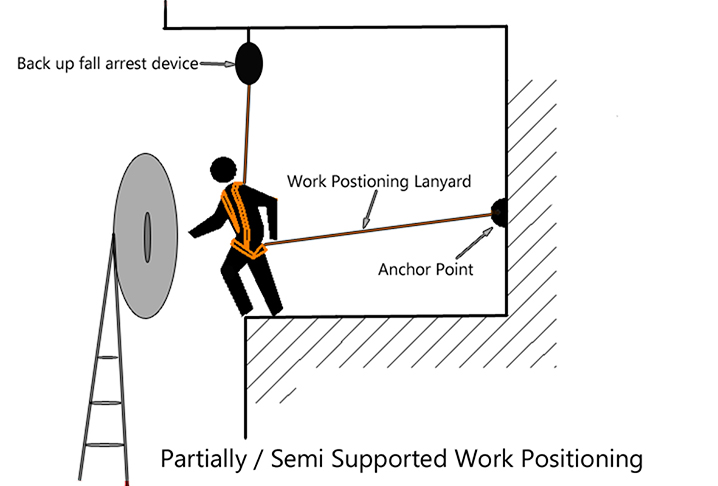

Rope Access and Work Positioning Applications

Rope access is a personal suspension access method that uses ropes. It allows a user to gain access between levels where there is no conventional access means, such as ladders, stairs or other structure. Two independent single point anchors are used for each access position. The main suspension rope or “working line” is rigged and is attached to both anchors. A second rope is also rigged and is attached to both anchors, known as the safety or “back-up” line. A fall-arrest device attaches to the back-up rope and provides fall-arrest protection in the event that the working line fails.

Work positioning is a similar access technique to rope access and also requires two independent single point anchors with a working line and safety back-up line. In rope access, the weight of the user is fully suspended from the working line whereas in work positioning the user is partially supported by the working line and partially supported by available structure. Further details can be found in BS 7985: 2013 and BS 8437: 2005.

Rescue Application

Rescue systems and techniques facilitate the rescue of a user (the Rescuee), by a remote access or an accompanied access means using ropes or other forms of lifeline, by the person performing the rescue (the Rescuer). Single point anchors provide the attachment means for these rescue systems. In the remote technique, the Rescuee is accessed by the Rescuer whilst the Rescuer remains in a place of safety. In the accompanied technique, the Rescuee is accessed by the Rescuer by the Rescuer descending to the same elevation as the Rescuee.

Emergency Descent / Evacuation Application

Emergency descent systems allow a user to rapidly descend from one level to a place of safety, in an emergency situation such as a fire. Single point anchors provide the attachment means for these types of system.

Applicable UK Standards & Guidance

Personal fall protection equipment – Type C Anchor devices

Personal fall protection equipment — Anchor devices — Recommendations for anchor devices for use by more than one person simultaneously

Personal fall protection equipment. Anchor systems

Personal fall protection equipment – Anchor systems – System design, installation and inspection – Code of practice

Testing of Roof Anchors on Roof Systems

BS EN 795 and the 89/686/EEC Directive

Code of practice for selection, use and maintenance of personal fall protection systems and equipment for use in the workplace

Levels of Safety

Work Restraint

Where it is reasonably practicable to do so anchor devices should be positioned such as to provide Work Restraint. The position of the anchor device together with the specified combination of user equipment will prevent the user from reaching a position from where they can fall.

Fall Arrest

Where it is not reasonably practicable to install an anchor device such that it provides Work Restraint, it may be positioned such that it allows a fall to be arrested. A Fall Arrest System will allow the user to reach a position from where they can fall, but minimise the distance and consequences of a fall, should one occur.

Rope Access & Work Positioning

Work positioning and rope access require two independant anchor points, one for the ‘working’ line, and a second for attachment of a back up fall arrest system. The user must remain attached to the fall arrest systems when connected to the work positioning system.

Design Considerations

The implementation of a fall protection system is a design process and it is recommended that BS 7883: 2019 is consulted by all parties involved.

Access & Maintenance Strategy

A personal fall protection system should only be considered where designing out the risk or installing means of collective fall prevention, such as edge protection, are not reasonably practicable. A formal Access & Maintenance Strategy Plan should be developed which considers the access & maintenance requirements of a building or structure over its life.

Access & Egress

Consideration should be given to how a user will access the system. Will a means of access other than a permanent staircase be required e.g. Fixed vertical ladder, powered access equipment, secured portable ladder

Selection of Equipment

Regulation 6 of the Personal Protective Equipment at Work Regulations 1992 requires an assessment to ensure that equipment selected is suitable for the role in which it is intended to be used. The equipment should have the characteristics to defeat the risks involved and should be correct for the circumstances of use.

The Layout

Where it is reasonably practicable to do so, the layout of the fall protection system should allow the user to reach all areas that require access, whilst allowing the task to be performed in those areas and minimising the fall-related risks to acceptable levels. Positioning of single point anchors is paramount in order to achieve the above.

Number of Users

Single point anchors have limitations in terms of how many users may be connected at any one time and the maximum user mass, both of which influence how strong the single anchor point installation needs to be.

Design Loads

As can be seen from the requirements within BS 8610, different applications need different configurations and strengths of single point anchor. The structure in which the single point anchor is to be installed must be capable of supporting any loads imposed with their associated factors of safety.

Rescue

The organising and planning of work at height is to include planning for emergencies and rescue, according to Regulation 4 of the Work at Height Regulations 2005. Single point anchors for rescue should be designated as such and should be installed in appropriate positions. Users who are left in suspension after experiencing a fall that has been arrested, or users who have become incapacitated whilst working using rope access techniques, are examples of a situation where immediate rescue would be required.

A rescue plan therefore needs to be in place, along with the resources and approach needed to perform a rescue, for instance trained and competent personnel, suitable rescue equipment and carrying out realistic rescue rehearsals.

User Considerations

Competence

It is a requirement of the Work at Height Regulations 2005 that persons involved in work at height, including those planning, managing & supervising work at height are competent to do so.

Personal fall protection systems require a higher level of competence from the user than collective fall protection systems, such as edge protection. Fall Arrest systems require a higher level of competence from the user than Work Restraint systems.

Users of Horizontal Fall Protection Systems must have the necessary level of knowledge, skill, experience & training in order to use the system safely.

User Equipment

Regulation 10 of the Personal Protective Equipment at Work Regulations 1992 requires that equipment should be used in accordance with the employer’s instructions, which should in turn be based on the manufacturer’s instructions for use. It should be used only after adequate training and instructions have been given to the user so they understand why and how where and when it is to be used.

The type of equipment to be attached to the single point anchor must be stated within the OEM Manual and the use must be limited those applications as authorised.

For example, a restraint system may inadvertently become a fall-arrest system where the user selects, or is issued a longer lanyard than specified. This may result in a fall to the ground either due to anchor failure, or there may be insufficient clearance below the system in which to arrest a fall. Incorrect selection of user equipment can have catastrophic consequences.

Rescue Planning

The Work at Height Regulations 2005 requires that the planning of work at height includes planning for rescue. When planning work with personal fall protection systems, it is critically important that a rescue plan is in place, along with the resources needed to effect a rescue i.e. trained and competent personnel, a rescue plan, suitable rescue equipment.

Energy Dissipation

In the event of a fall, the anchor device is dynamically loaded.

Some types of single point anchor have a built in means of reducing potential loads that may be transferred back to the structure that it is fixed to. However, for fall arrest applications the user should always use a connecting device that limits the amount of load generated in the event of a fall to </=6kN, e.g. an energy absorbing lanyard.

Single Point Anchor with Energy Dissipation

Single point anchor device with integral energy dissipation. In the event of a fall the anchor is designed to deform, reducing the loading to the structure to which it is fitted.

Lanyard Energy Absorber

Performance requirements specified for personal fall arrest equipment require that in the event of a fall the impact force on the user does not exceed 6kN.

This is typically achieved by incorporating a tear webbing pack or shock pack in an energy absorbing lanyard or braking system in a self retracting lifeline.

Inspection

Provision & Use of Work Equipment Regulations (PUWER)

Regulation 6 requires that inspections of work equipment are made and that records of the inspections are maintained.

Personal Protective Equipment at Work Regulations (PPEAW)

Regulation 7 obliges the PPE provider to ensure it is maintained in an efficient state, working order and in good repair

BS EN 365

Requirements, 4.4b, recommends that the periodic examination frequency for PPE used against falls from a height shall be at least every 12 months, but should take into account factors such as legislation, equipment type, frequency of use and environmental conditions, (i.e. a higher examination frequency may be necessary – e.g. every 6 months).

Clause 3.3 of BS EN 365 states that a person who carries out periodic examinations should be competent. They should be knowledgeable of current periodic examination requirements, recommendations and instructions as issued by the equipment manufacturer. They should be capable of identifying and assessing the significance of defects, should initiate any required corrective action and should have the necessary skills and resources to do so.

Lifting Operations and Lifting Equipment Regulations (LOLER)

Regulation 9 requires that lifting equipment and accessories used for lifting persons should be thoroughly examined every six months. This would cover single point anchors used for rope access, work positioning and rescue purposes.